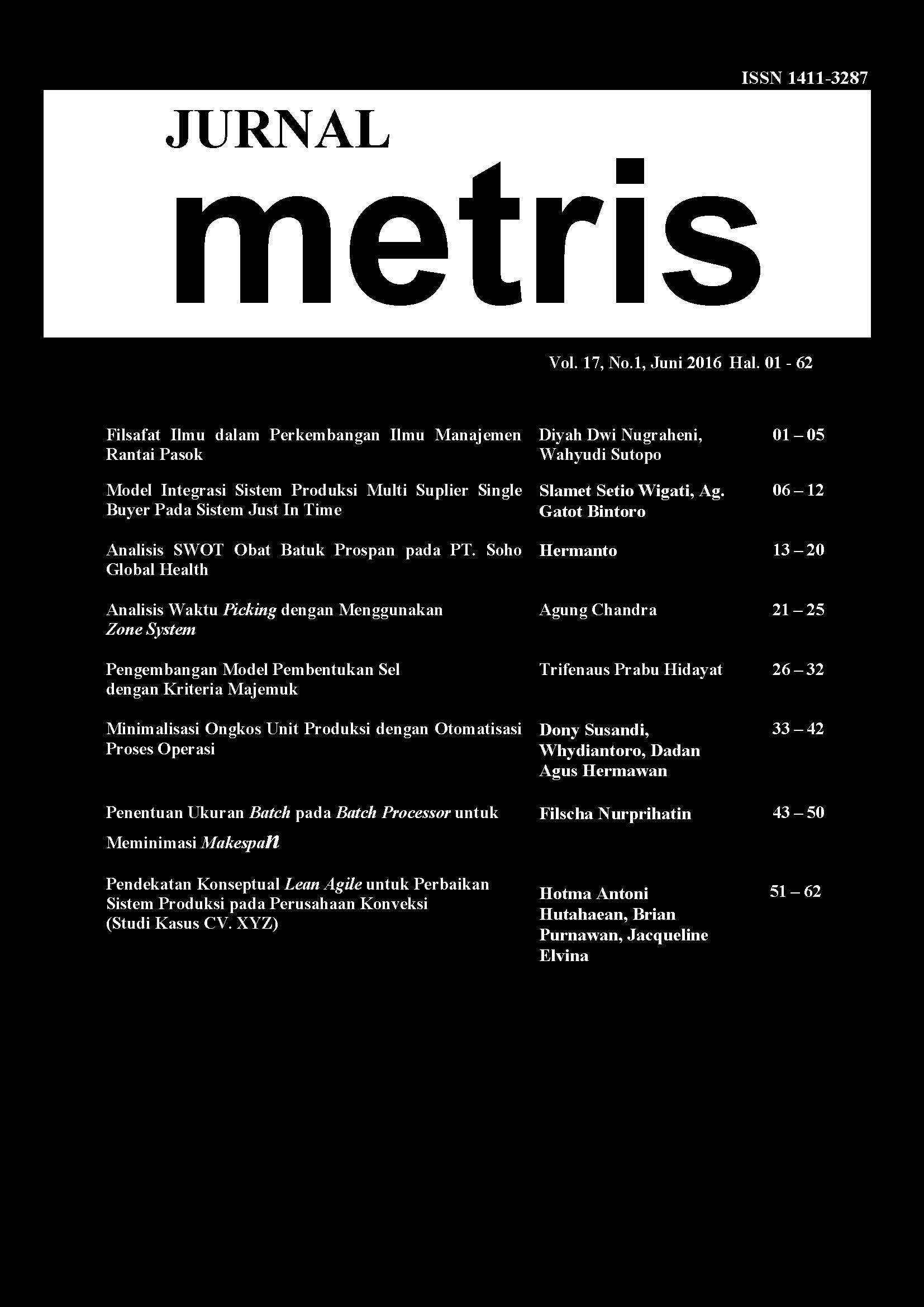

Pendekatan Konseptual Lean Agile untuk Perbaikan Sistem Produksi pada Perusahaan Konveksi (Studi Kasus CV. XYZ)

Keywords:

Agile Lean, 5S, tools implementationAbstract

This study discusses the proposed improvements to the production system using lean agile supply chain approach. In the middle’s company, one of which is the problem that the turnaround time is too long or waiting waste and defect waste. Under the existing conditions, the company's production system to improve production speed in response to rapid changes in consumer interest and improve product quality. There are 3 stages used in the Lean Agile approach that are phase planning, execution, and delivery. The data obtained from the company necessary, through observation, and through direct measurement. Based on the research that has been made known that there are four kinds of defects that are CTQ (Critical to Quality), four types of defects are defects hollow, fibrous defect, defect loose stitches, and gross defects / stains. In the planning process we already know what the model variant is desired by consumers is a model school crest motif symbol, foundations, public, and school patron, besides the application of a pull system and didapti empowerment of teams who want to make changes repairs.Proposed improvements are the main target of this research, which at this stage 5S approach work attitude, the manufacture of tools to support performance changes, as inputting the manufacture of flexible software, and implementation of design improvements that have been made into the main ingredients in providing a solution to improve the speed work and minimize the occurrence of defects in order to improve quality.